Vacuum Casting - Urethane casting

3ERP is fully capable of handling your vacuum casting and silicone molding needs. With years of expertise in the field, we can fabricate your parts to the highest standard and with fast turnarounds.

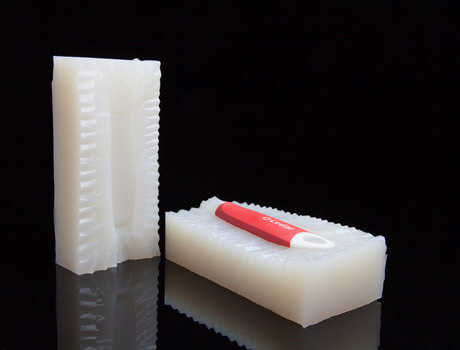

Vacuum casting is a great way to make rigid or flexible parts, and is ideal for prototypes, engineering testing, concept proofing and display demos. These parts can be made from hundreds of casting polymers.

Contact us today for more information.

Advantages of CNC Machining With Huapin

1 Fast turnaround

3ERP can provide up to 20 parts in 15 days or less, depending on part specification and volume.

2 Affordability

Silicone molds are less expensive than the tooling used for injection molding, resulting in low prices.

3 Capable of producing large parts

Depending on the type of equipment used, vacuum casting can to create very large parts.

4 Superior surface finish to injection molding

The vacuum process removes air bubbles and allows the material to capture fine details.

5 Color options

Coloring pigments can be added to the resin for a variety of color options.

6 Repeatability

Silicone molds can be used around 20 times before they need replacing.

Common Vacuum Casting Applications

- Visual prototypes

- Market testing

- Concept proofs

- Cases and covers

- Cases and covers

- Trade shows

- Low-volume production

What is Vacuum Casting?

Vacuum casting is a manufacturing technology that uses a vacuum to draw liquid material into a mold. It differs significantly from injection molding, which pushes liquid material into a mold using a screw.

The process of vacuum casting offers significant advantages, and is particularly useful for parts that have undercuts or fine details.

The process starts with a master model, which 3ERP creates using one of its CNC machining centers — though 3D printing can also be used. This master model is then immersed in liquid silicone, which is cured and becomes the mold.

Once it has been cut and the master model removed, the silicone mold can be put to use. This stage involves pouring casting resin into the mold, as the vacuum removes bubbles and air pockets to ensure a smooth finish.

The resin part is then cured and removed from the silicone mold, which can be reused around 20 times.

Each resin part is an exact copy of the original master model.

Vacuum Casting Process

With high precision milling & turning machines, we are able to catch super tight tolerance for prototype machining & production. Parts will be made accordingly to our customers’ specification. If 2D drawings are not available, you can also indicate with ISO 2678. The table below is the ISO 2678 standard for your reference

| Step 1:Master building | Masters are 3D solids of your CAD designs. They are usually made by CNC machining or with 3D Printing. Making Master in 40° temperature. After finish and inspect the masters, we will move to silicone mold making. |

| Step 2: Mold making | Casting molds are made from liquid silicone. Half-Fill the casting box with liquid silicone, Heat the casting box until silicone is fully cured and then allowed to cure in an oven for 16 hours. Fill with extra silicone liquid which is also heated & cured. Once dried, the mold is cut open and the master removed. |

| Step 3: Make the parts | Poured the casting resins into the empty cavity to create a highly accurate copy of the original. It’s even possible to overmold with two or more materials. Silicone molds are typically good for 20 or so copies of the master pattern. |

Vacuum Casting Technical Specifications

With high precision milling & turning machines, we are able to catch super tight tolerance for prototype machining & production. Parts will be made accordingly to our customers’ specification. If 2D drawings are not available, you can also indicate with ISO 2678. The table below is the ISO 2678 standard for your reference

| Typical lead time | Up to 20 parts in 15 days or less, depends on the part specification and volumes. |

| Accurate | ± 0.3% (with lower limit on ± 0.3 mm on dimensions smaller than 100 mm) |

| Minimum wall thickness | To ensure that the mold is filled properly, a wall thickness of at least 0.75 mm is necessary. For best results, we recommend a wall thickness of at least 1.5 mm |

| Maximum part dimensions | The size of the mold is limited by the dimensions of the vacuum chamber (1900 x 900 x 750 mm) and by the volume of the product (maximum volume: 10 liters) |

| Typical quantities | Up to 25 copies per mold (depending on the mold’s complexity and the casting materials) |

| Color & Finishing | Pigment is added to the liquid polyurethane prior to casting, custom painting and texture. |