Plastic injection Molding

We provide high-quality injection parts on demand. Injection molding is the most cost-effective method for mass production of plastic parts and provides consistent quality for small to large volumes. Compared with CNC machining and even 3D printing, molding also has the most materials, colors and configurations.

Our plastic injection molding process produces custom prototypes and end-use production parts in 15 days or less. We use aluminum molds that offer cost-efficient tooling and accelerated manufacturing cycles, and stock more than 100 different thermoplastic resins.

Injection Molding

In this process, melt the resin under high pressure into the cavity of the metal mold to form the desired mold shape. After cooling the mold, get the desired product shape. A single cycle to make a finished part may take anywhere from a few seconds to minutes depending on part complexity and size.

At Hua-pin, we offer rapid tooling, mold making, and die manufacturing for both low-volume production, mass production, and prototyping. Our expertise includes steel, and aluminum tooling, and mold maintenance, redesign services.

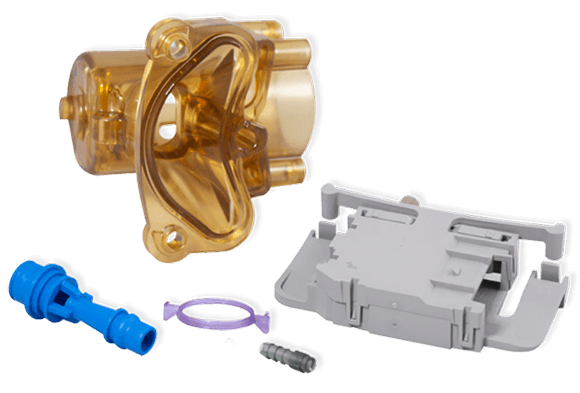

Over Molding

Over molding is a process used to combine at least two materials into one project. At Hua-pin, we can mold a thermoplastic material into a second material to leverage certain performance and characteristic attributes of the materials to complement functionality.

Overmolding is very effective for manufacturing composite parts, and its cost is lower than other production techniques that require the assembly of individual parts. Over molded parts typically consist of a substrate and the over molding material. Substrate material include metal,plastic,glass and more.

Insert Molding

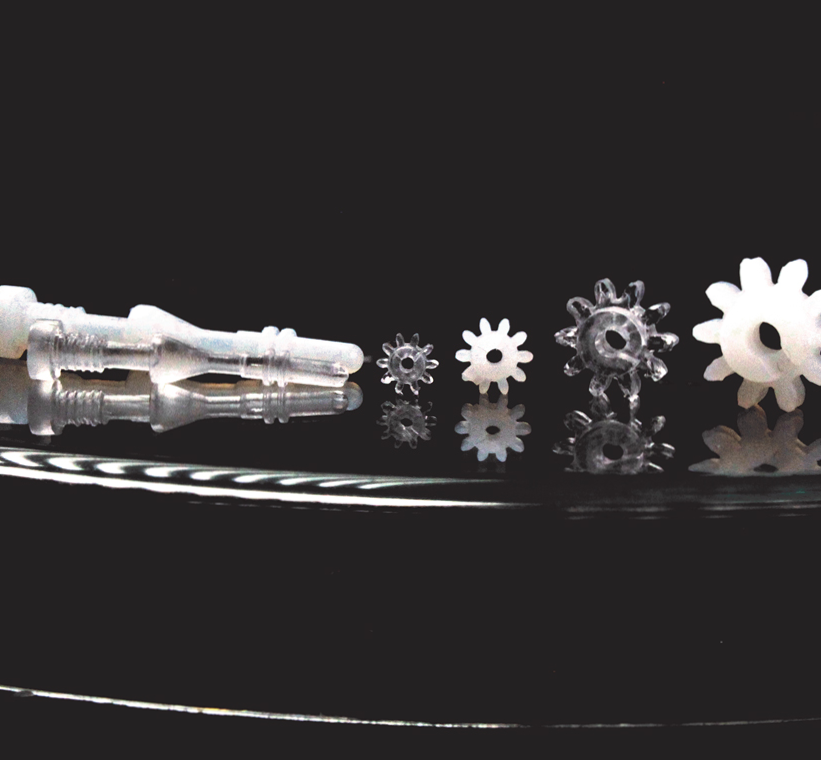

What is insert molding? The resin is injected into the mold after the pre-prepared insert of different materials, and the fused material is bonded and solidified with the insert to make the molding method of integrated products.

Through our expertise in cross-technology fabrication, we can use sheet metal and CNC machining to make units of your metal part and employ insert molding to introduce plastic parts. Insert molding can be used in making tools that are sharp and require a grip.

What is Plastic Injection Molding

Plastic injection molding is by far the most common way to produce large volumes of finished plastic parts for every kind of commercial and industrial use.

Molten resin is injected under high pressure into the cavity of a metal die and then rapidly cooled, forming a solid shape. A single cycle to make a finished part may take anywhere from a few seconds to minutes depending on part complexity and size.Plastic injection molding is a manufacturing process where resin in a barrel is heated to a molten state, then shot into a mold to form a final production-grade thermoplastic part.

The Injection Molding Process

1.Production cost: Compared to other processes, the price of each piece through injection molding is significantly lower, especially as the number of survivors increases to several thousand.

2.Precise dimension:The mold can be machined by CNC with high precision, with tolerances up to the national standard GB/T 14486-2008, and is capable of producing thousands of identical parts.

3.Part quality: Under the condition of the same material and parts, the performance of molded parts is generally better than that of parts produced by other processes.

4.Material diversity: Choose from hundreds of manufacturing materials including various grades of thermoplastics, metals, and elastomers.

The Injection Molding Process

Below you will find a list of the materials that we can work with at Hua-pin. Exotic and special materials can be purchased if required. Please kindly ask us when in doubt.

| Material Name | Abbreviation | Material Name | Abbreviation |

| Acrylonitrile Butadiene Styrene | ABS | Polyether Ether Ketone | PEEK |

| Acrylonitrile Styrene Acrylate | ASA | Polyetherimide, Ultem | PEI |

| Cellulose Acetate | CA | Polyether Sulfone | PES |

| Copolyester | COPO | Polyethylene Terephthalate, Rynite | PET |

| High-Density Polyethylene | HDPE | Polylactic Acid | PLA |

| Liquid Crystal Polymer | LCP | Polymethyl Methacrylate, Acrylic | PMMA |

| Low-Density Polyethylene | LDPE | Acetal Polyoxymethylene, Delrin | POM |

| Polyamide 6, Nylon 6 | PA 6 | Polypropylene | PP |

| Polyamide 6/6, Nylon 6/6 | PA 6/6 | Polyphthalamide | PPA |

| Polyaryl Amide | PARA | Polyphenylene Sulfide, Ryton | PPS |

| Polybutylene Terephthalate, Valox | PBT | Polystyrene | PS |

| Polybutylene Terephthalate-Polyethylene Terephthalate | PBT-PET | Polystyrene-Polyphenyl Ethers, Noryl | PS-PPE |

| Polycarbonate | PC | Polysulfone, Udel | PSU |

| Polycarbonate-Acrylonitrile Butadiene Styrene | PC-ABS | Polyvinyl Chloride (Shore D) | PVC |

| Polycarbonate-Polybutylene Terephthalate, Xenoy | PC-PBT | Polyvinylidene Fluoride | PVDF |

| Polycarbonate-Polyethylene Terephthalate | PC-PET | Styrene Acrylonitrile | SAN |

| Polycyclohexylenedimethylene Terephthalate | PCT | Thermoplastic Polyolefin | TPO |

| Polyethylene | PE | Thermoplastic Polyurethane (Shore D) | TPU |

| Polyethylene-Polypropylene | PE-PP | Custom-sourced Resin | / |

| Polyethylene-Polystyrene | PE-PS | Customer-supplied Resin | / |

| Polyether Block Amide | PEBA |

Application of Plastic Injection Molding

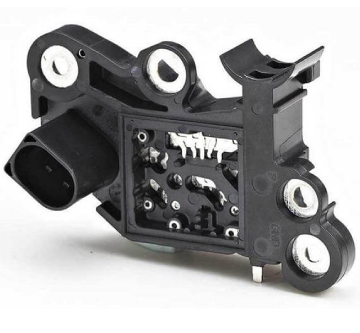

Automotive Industry

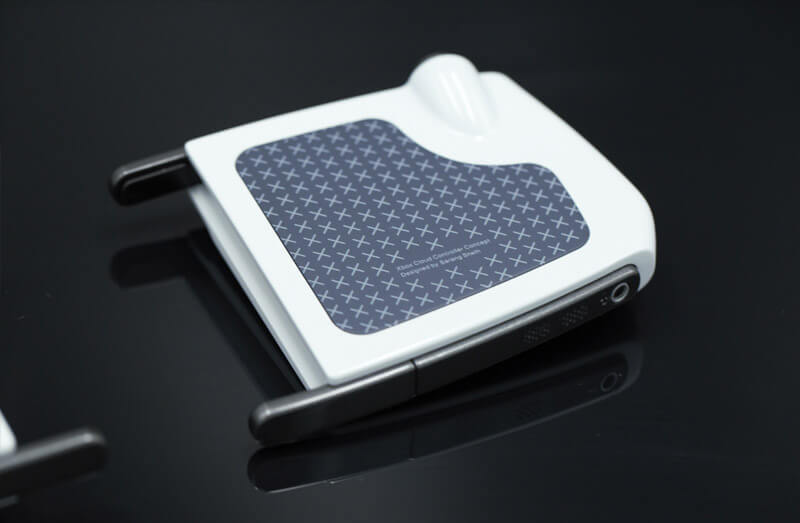

Consumer Products

Medical Equipment

Electronic Products

Space Industry

Advantages of Injection Molding

Injection molding is an excellent option for the large-scale production of plastic parts and components. The advantages of using injection molding include:

- Efficiency: The mold injection process is highly efficient, facilitating short lead times for large orders.

- Superior detail: The high pressure of injection ensures that the melted material reaches every crevice of the mold before curing. This enables design engineers to incorporate complex geometrics and intricate elements into their designs.

- Affordability: Fast and efficient production ensures a low cost per part, while high production volumes produce further economies of scale. Aluminum a cost-effective and readily available material can be used for tools to control costs.

- High-volume production: Injection molding with steel molds can facilitate high-volume production of parts into the millions.

- High tensile strength: Injection-molded parts may be reinforced by adding fillers into the liquid resin that improves tensile strength.

- Ready-to-go finish: With the proper treatment, injection-molded parts come out of the mold with a smooth finish that requires no further refinement.

Other Types of Injection Molding

There are two common variants on the injection molding process: overmolding and insert molding.

Overmolding

Overmolding uses injection molding to create a part from multiple materials. This process adds an injection-molded layer of material over an existing injection-molded workpiece. The overmolding process produces chemically bonded parts made from multiple materials.

Overmolding is often cheaper and more effective than manufacturing methods that require the creation and assembly of component material parts separately. The process can also be used to build layered parts from scratch or to add a resistant outer layer to existing plastic parts and tools to provide a more rugged exterior. Toothbrushes consisting of a solid plastic body and rubberized grip are a common example of an overmolded product.

Insert Molding

Insert molding is similar to overmolding, but the substrate is not necessarily plastic and does not have to be produced via injection molding. For example, insert molding can be used to add a plastic coating to a pre-fabricated metal part.

Common parts made by insert molding include sharp handheld tools, such as scalpels, which consist of a metal blade partially housed within a plastic handle. Insert molding is also frequently used to create products that incorporate bushings, clips, and fasteners.

Our Molding Capabilities

At 3ERP, our experienced team produces injection-molded products of the highest quality. We use injection molding in tandem with our rapid tooling capabilities, allowing us to create detailed custom parts quickly and efficiently. We are pleased to provide injection mold services in a number of materials and finishes to suit the needs of any industry or application.

Our capabilities include:

Materials

- Acetal polyoxymethylene (POM)

- Nylon 66 (PA66)

- High-density polyethylene (HDPE)

- Polybutylene terephthalate (PBT)

- Glass-filled polycarbonate (PC-GF)

- Polyethylene terephthalate (PET)

- Polyphenylene sulfide (PPS)

- Polystyrene (PS)

- Thermoplastic elastomer (TPE)

- Acrylonitrile butadiene styrene (ABS)

- Glass-filled, polyamide (PA-GF)

- Low-density polyethylene (LDPE)

- Polycarbonate (PC)

- ABS polycarbonate (PC-ABS)

- Polymethyl methacrylate (acrylic) (PMMA)

- Polypropylene (PP)

- Polystyrene + polyphenyl ethers (PS-PPE)

- Thermoplastic vulcanizates (TPV)

Finishing Options

- Polishing

- Pad printing

- Silk screening

- Custom color painting

- Laser finishing

- Heat staking

- Texture finishing