Injection Molding

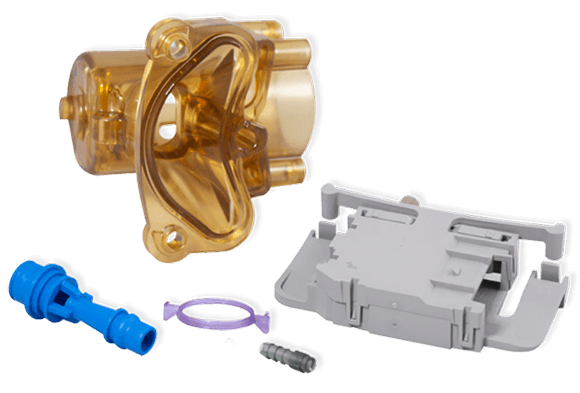

Injection molding is a manufacturing process by which molten material is injected into a mold and cured to create intricate shapes. The method is used to create parts in large quantities for use in a wide range of industries ranging from medicine to aerospace to consumer products.

At 3ERP, we offer injection mold prototyping services to assist our customers with testing their designs for manufacturability and functionality.

The Injection Molding Process

During the injection molding process, material is melted and mixed in a barrel where a reciprocating screw melts the material and feeds it into a split mold. The liquid material is then injected into a prototype mold cavity at high pressure to force it into all mold cavities before it cools and solidifies into the predetermined design shape.

This process is highly effective for the large scale production of industrial parts and components, and allows for the creation of products with multiple materials using repeated injection methods. Prototype injection molding wastes less material than other manufacturing processes and saves time by reducing the number of steps necessary to produce a given product.

Common Applications

Injection molding is used to manufacture parts for a number of industries, including:

- Medical devices

- Packaging

- Automotive

- Food containers

- Aerospace

- Toys

- Electronic

- Plastic prototypes

Advantages of Injection Molding

Injection molding is an excellent option for the large-scale production of plastic parts and components. The advantages of using injection molding include:

- Efficiency: The mold injection process is highly efficient, facilitating short lead times for large orders.

- Superior detail: The high pressure of injection ensures that the melted material reaches every crevice of the mold before curing. This enables design engineers to incorporate complex geometrics and intricate elements into their designs.

- Affordability: Fast and efficient production ensures a low cost per part, while high production volumes produce further economies of scale. Aluminum a cost-effective and readily available material can be used for tools to control costs.

- High-volume production: Injection molding with steel molds can facilitate high-volume production of parts into the millions.

- High tensile strength: Injection-molded parts may be reinforced by adding fillers into the liquid resin that improves tensile strength.

- Ready-to-go finish: With the proper treatment, injection-molded parts come out of the mold with a smooth finish that requires no further refinement.

Other Types of Injection Molding

There are two common variants on the injection molding process: overmolding and insert molding.

Overmolding

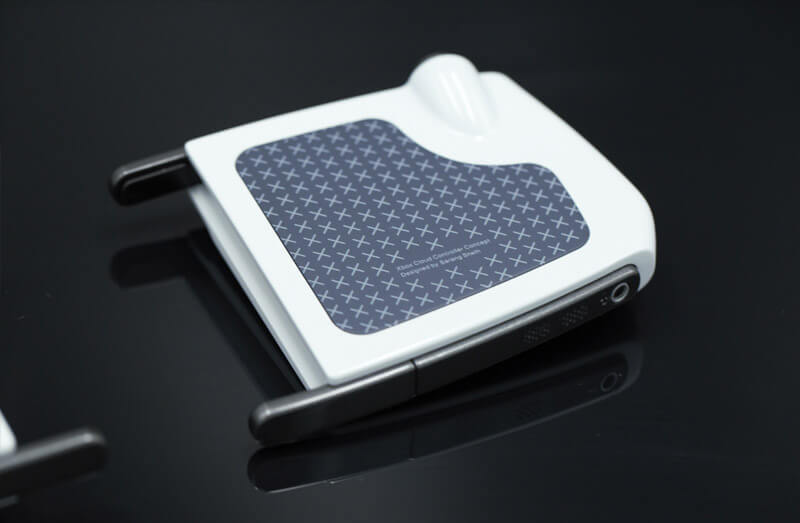

Overmolding uses injection molding to create a part from multiple materials. This process adds an injection-molded layer of material over an existing injection-molded workpiece. The overmolding process produces chemically bonded parts made from multiple materials.

Overmolding is often cheaper and more effective than manufacturing methods that require the creation and assembly of component material parts separately. The process can also be used to build layered parts from scratch or to add a resistant outer layer to existing plastic parts and tools to provide a more rugged exterior. Toothbrushes consisting of a solid plastic body and rubberized grip are a common example of an overmolded product.

Insert Molding

Insert molding is similar to overmolding, but the substrate is not necessarily plastic and does not have to be produced via injection molding. For example, insert molding can be used to add a plastic coating to a pre-fabricated metal part.

Common parts made by insert molding include sharp handheld tools, such as scalpels, which consist of a metal blade partially housed within a plastic handle. Insert molding is also frequently used to create products that incorporate bushings, clips, and fasteners.

Our Molding Capabilities

At 3ERP, our experienced team produces injection-molded products of the highest quality. We use injection molding in tandem with our rapid tooling capabilities, allowing us to create detailed custom parts quickly and efficiently. We are pleased to provide injection mold services in a number of materials and finishes to suit the needs of any industry or application.

Our capabilities include:

Materials

- Acetal polyoxymethylene (POM)

- Nylon 66 (PA66)

- High-density polyethylene (HDPE)

- Polybutylene terephthalate (PBT)

- Glass-filled polycarbonate (PC-GF)

- Polyethylene terephthalate (PET)

- Polyphenylene sulfide (PPS)

- Polystyrene (PS)

- Thermoplastic elastomer (TPE)

- Acrylonitrile butadiene styrene (ABS)

- Glass-filled, polyamide (PA-GF)

- Low-density polyethylene (LDPE)

- Polycarbonate (PC)

- ABS polycarbonate (PC-ABS)

- Polymethyl methacrylate (acrylic) (PMMA)

- Polypropylene (PP)

- Polystyrene + polyphenyl ethers (PS-PPE)

- Thermoplastic vulcanizates (TPV)

Finishing Options

- Polishing

- Pad printing

- Silk screening

- Custom color painting

- Laser finishing

- Heat staking

- Texture finishing