CNC Machining Services

CNC machining usually refers to computer-controlled precision machining, CNC machining lathes, CNC milling machines, CNC turning and milling machines, etc.CNC is a new processing technology, the main work is to compile the processing program.

What is CNC Machining Service?

Numerical control device in the computer through input device in Numbers and character encoding way after a series of processing, the recorded information via the servo system and the programmable controller to the machine tool spindle and feed actuators issue instructions, machine body, in accordance with these instructions, and in conjunction with the test feedback device, the workpiece machining various actions, such as the cutting tool relative to the workpiece trajectory, feed speed and displacement requirements to realize automatic control, so as to complete the workpiece machining.

Advantages of CNC Machining With Huapin

There are huge numbers of CNC machining service providers. Why should you choose us? Here are the top 3 reasons:

1. Experience

Our engineers have built up rich, deep experience from many previous projects, so they can handle complex and precision parts in several industries without a problem.

2. Advanced Equipment

3ERP has extensive in-house equipment for both manufacturing and testing. Your parts will be manufactured and inspected with our advanced in-house equipment, including HAAS 3-, 4-, and 5-axis CNC milling, Hexagon CMM, and Olympus XRF analyzer

3. Fast Turnaround

On average we return quotes within 24 hours, parts ship within 7 days or less, and we have a 99% on-time delivery and quality rate.

HuaPin's CNC Machining Services is Trusted by Worldwide Engineers

HuaPin's CNC Machining Services is Trusted by Worldwide Engineers

Standard Tolerances

With high precision milling & turning machines, we are able to catch super tight tolerance for prototype machining & production. Parts will be made accordingly to our customers’ specification. If 2D drawings are not available, you can also indicate with ISO 2678. The table below is the ISO 2678 standard for your reference

| Tolerance Lever | Overall Dimension Range | ||||||

| Specifications | <<3, >0.5 | <<6, >3 | <<30, >6 | <<120, >30 | <<400, >120 | <<1000, >400 | <<2000, >1000 |

| Tolerance Standard | |||||||

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

| M | ±0.1 | ±0.1 | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 |

| C | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 | ±3 |

| V | – | ±0.5 | ±1 | ±1.5 | ±2.5 | ±4 | ±6 |

CNC Machining Materials & Finishes

Plastic: ABS, ABS+PC, PC, PP, PEEK, POM, Acrylic (PMMA), Teflon, PS, HDPE, PPS, DHPE, PA6, PA66, PEI, PVC, PET, PPS, PTFE,etc.

Metal: Aluminium, Brass, Copper, Magnesium, Titanium, Stainless Steel, Tin, Zinc, etc.

These are the most common materials for CNC prototyping and production parts. For more material information with price and suitable finishes, please click to review the form below. If you can’t find the material you need, please contact our team.

Review More Materials & Finishes Options

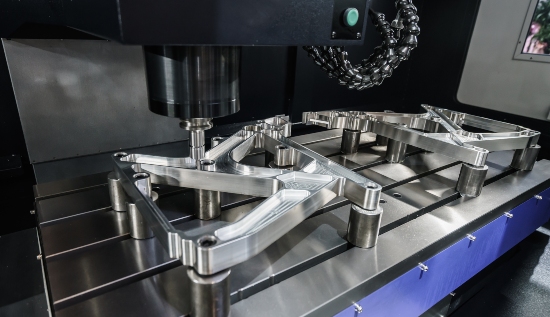

CNC Milled Parts

In the traditional metal cutting machine tool, by changing the parameters such as the moving track and moving speed of the tool, the tool can cut the workpiece and finally produce the qualified parts.

CNC milling is available in various sizes, capacity and axial configurations. They can work with a variety of materials like plastic, resins, aluminium and more, but are specially designed for machining harder materials like stainless steel and titanium with high precision and accuracy.

Explore Our CNC Milling Capabilities

CNC Turned Parts

Operations are designed for making final parts with axial and radial holes, internal diameters, grooves and slots. Our CNC turning centres are capable of high-speed turning of both plastic and metals to create end-parts with complex external geometries, cylindrical features, threads and internal bores.

Explore Our CNC Turning Capabilities

FAQ

What are the types and USES of CNC machining materials?

We work with a wide range of plastic and metal materials including magnesium, steel, aluminum, brass and titanium to make tooling for plastic injection molding and pressure die casting.

What kind of application for CNC?

Rapid Tooling: Because CNC can be applied to virtually any material, it is perfect for rapid tooling, i.e., creating fixtures or molds.

Rapid Prototyping: Low cost and speed of products make CNC a great option for prototyping.