When it comes to milling and turning machines, there are a lot of details that make a significant difference in your workflow. No single machine can handle every possible manufacturing operation so it’s wise to note the characteristics that would be most suitable to one’s operations. There are many such calculations to keep in mind, but one of the most important distinctions to make when it comes to choosing a machining set-up is whether the configuration should be vertical or horizontal.

As both types of configurations have their own specific drawbacks and advantages with each type of machine, this article aims to examine under what conditions each set-up is most warranted.

The Basics

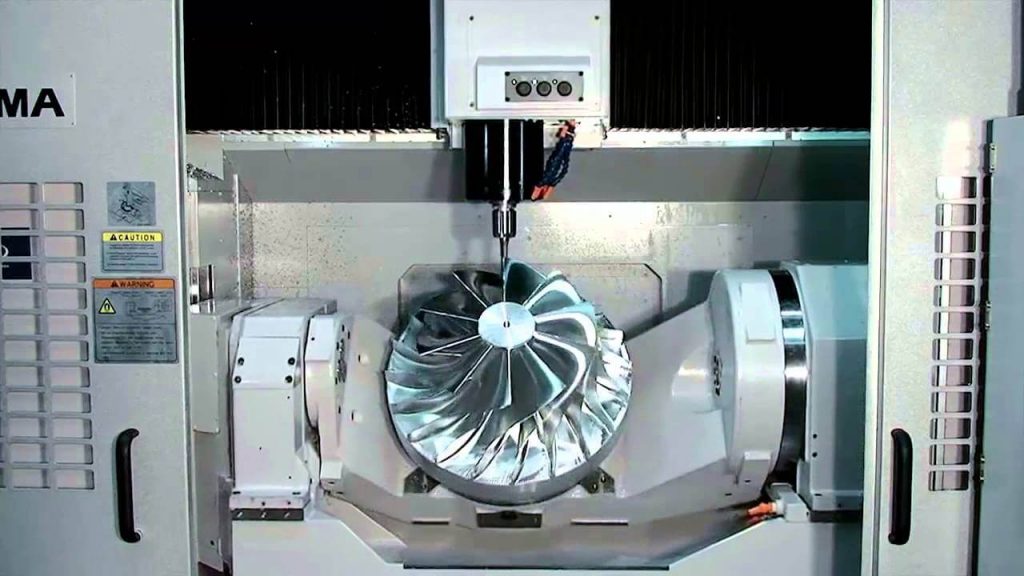

Vertical Machining Centers actually comprise the majority of milling machinery across industries like metalworking, which can be attributed to their lower costs in comparison with Horizontal systems. As the name implies, vertical milling machines have a vertical orientation on their cutting head or spindle. The specifics of the milling controls may vary from machine to machine.

The two main types of vertical mills are turret mills and bed mills. With turret mills, the spindle remains fixed in place, while the bed portion of the machine holds the material. This bed moves horizontally or vertically, allowing for the machine to manipulate the position of the material in both directions. The turret mill is an extremely versatile device but it can be limited by the size of the pieces it produces.

Bed mills move the materials along the horizontal axis with a spindle that is restricted to the vertical axis. The spindle can move up and down as needed and process the material into shape. Bed mills have a pretty good range of movement, as the spindle part combines with the horizontal movement of the bed allowing the milling of a wide variety of shapes and depths.

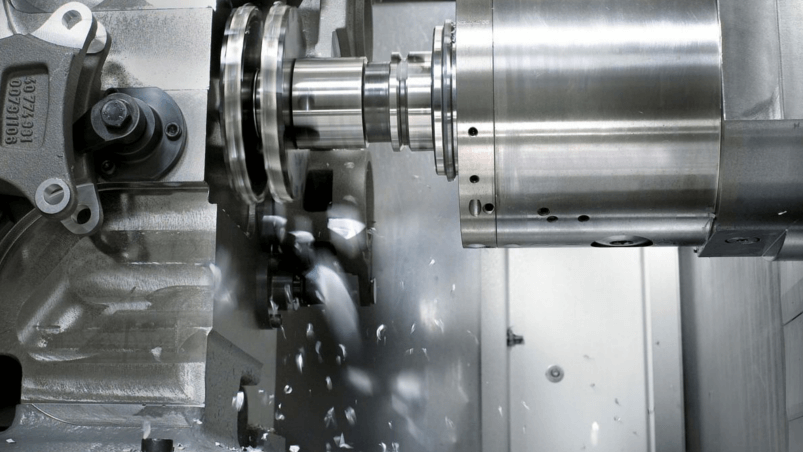

In contrast, a horizontal milling machine utilizes a horizontal arbor to mount the cutting surfaces. The horizontal mill’s cutters resemble the blade of a circular saw somewhat, with a crucial difference being that they are generally thicker, smaller and their shape offers speedier milling than the spindles on their vertical counterparts. The use of the arbor and its length can also mean that horizontal mills can use multiple cutters at a time.

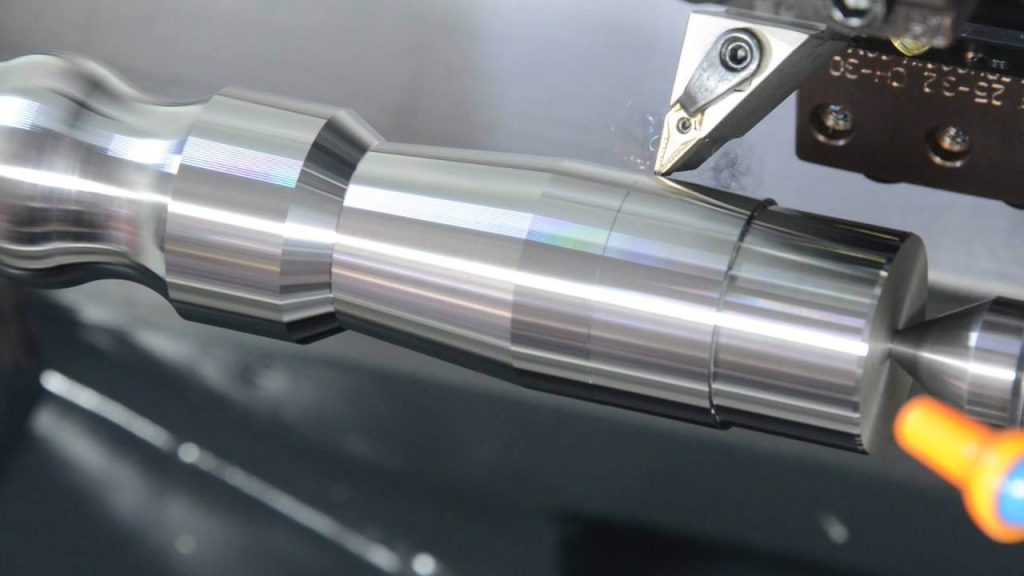

When it comes to CNC turning centers, much like the milling centers, they can also be divided into horizontal and vertical configurations. Horizontal turning centers are the more prominent type across most industries. They have a spindle that is horizontally oriented, with tools mounted out of the side of the tool holder. This helps them cut across the object being processed. Much like it’s the milling counterpart, this type of turning center also benefits from gravity as it pulls the chips away from the work-piece.

Vertical turning centers are also called vertical turret lathes or VTL. The vertical and horizontal turning centers are very similar but their configuration and shape are upended allowing the headstock to sit on the floor and the faceplate to become a horizontal rotating table. Inverted vertical turning centers are like the regular ones but they have reversed positions for the spindle and jaw chuck.

Vertical Machining – Pros & Cons

Vertical milling is most applicable to projects where the main focus of the object in question is on one particular side. This can be something like a large metal plate or a sinking die. They also have the benefit of being generally less complex than horizontal milling machines, being both cheaper and easier to use and maintain for this reason.

With vertical machining centers there are some variances based on what type it is. Turret mills are usually limited to smaller size projects due to how the two-axis movement can be challenging with larger pieces of material. In contrast, bed mills are better suited to projects requiring heavier, larger work-pieces (yet still far less proficient at processing such items when compared to horizontal mills).

Vertical mills have a far lower footprint than their vertical counterparts. This, along with the price-point, makes them desirable for smaller shops. They also have more users and thus have a larger pool of skilled machinists.

Where VMCs lack is the ability to produce in higher volumes and complexities. Weightier materials can also be a problem for the vertical machine’s operations as they can be harder to raise and lower.

Horizontal Milling – Pros and Cons

Despite the higher price point, horizontal mills are the preferable choice for more complex projects. The machines are more versatile and can work on more sides than the vertical ones. They are also better for heavier items and ones were cutting one or more grooves with a material is desirable. Horizontal mills have a better propensity for creating slots as well. They do well with heavier materials.

The machines can also allow for extra cutters for various applications, particularly inserting grooves more efficiently. On certain horizontal mills, beds can be rotated to enable milling at multiple angles rather than strictly on a horizontal plane. This movement of the bed also adds a bit more versatility to the machine’s arsenal.

Horizontal mills also have a far better chip evacuation. This comes down to the configuration making use of gravity to let the chips fall. Additionally, this is more conducive to a better surface finish and longer tool life.

In terms of drawbacks, the most critical one is the higher costs associated with horizontal milling machines. These costs can be as high as 3 to 4 times that of vertical mills. HMCs may also be harder to monitor, with parts being obstructed and the view of the project limited by the design. They are also larger, making them harder to place in a limited workspace.

Horizontal Turning – Pros and Cons

Horizontal turning centers are often quite flexible and have longer beds, which makes them more suitable for longer pieces like shafts. This gives them additional utility and versatility. They can also use parts like bar feeders and commonly have tailstocks, which are rare for vertical lathes.

Horizontal turning centers have been around longer and thus the majority of machines and experts tend to operate with this configuration. This also means there is a wider wealth of information available on these machines and their specific operations. Hiring and training tend to thus gear towards it, which can be an advantage of the machine itself.

Horizontal machines can be limited. When machining large diameter short parts, especially if they are heavy parts, the vertical turning centers work better. Chip flow and cleaning are also an issue with horizontal configurations.

Vertical Turning – Pros and Cons

his configuration is particularly beneficial for machining large, heavy and short objects. The downward pull of gravity contributes to the placement of the work-piece into the work holding. Another advantage is that the presence of gravity directs the chips away from the work-piece and into the pan or conveyor.

A lot of car parts are done vertically and typically with a twin spindle. One benefit of that is that you have gravity working for you; when you put the part in the chuck, it seats itself.

Having the spindle vertical, as opposed to horizontal, allows the spindle to be supported 360°, eliminating spindle droop and increasing the maximum weight allowable on the spindle. The additional support also dissipates the cutting forces created by heavy and or interrupted cutting. Eliminating spindle droop also allows capabilities for achieving better part flatness and perpendicularity accuracies.

Vertical turning centers also have a far lower footprint than their horizontal brethren, allowing shops to optimize floor-space. Oftentimes a vertical lathe may take up half of the footprint of a horizontal lathe, which can give it an edge in smaller shops.

Inverted vertical machines are also an option as they can allow for built-in automation that would be unavailable with horizontal. Here, the spindle comes over and picks up the part, whereas in a horizontal you need a robot or gantry to load it.

Chips can pose an issue for vertical lathes and turning centers if the part being processed is concave. This often results in the chips becoming internally trapped. Another issue that can arise is that of the chips falling down into the spindle itself. Protective measures and guarding has to be efficient.

Endnote

It’s also important to keep in mind that there are also various types of add-on parts and cutting heads that can be used to modify a horizontal mill to do vertical milling, or vice versa. This can serve as a cheaper solution when one type of machine runs into a possible roadblock. However, while such tools are great, they are still a limited solution compared to having the actual device on hand. Similarly, inverted vertical turning centers can also be something to look into, as they can add additional automation to the process.

Hope the information we provide helps. 3ERP offer CNC milling services and CNC turning services for both rapid prototyping and production. Contact our engineers if you need any further manufacturing suggestion.