Rapid prototyping and 3D printing are a true design-in pairing!

Rapid prototyping is a common process applied in many industries. The use of 3D printers for prototyping is a sensible way to cut down on time and money while expanding design possibilities. It puts companies in a position to conceive designs and ideas physically and quickly at a lower cost.

This blog will guide you on incorporating 3D printing into your rapid prototyping process while reducing costs and time to market.

What is rapid prototyping?

Rapid prototyping is the process of rapid manufacturing (non-final) to test design ideas and obtain data that will help improve future iterations. When designing a physical product, rapid prototyping allows you to experiment with different materials, sizes, shapes, colors, and more that affect the shape, fit, and function. You can then use the experience gained from these experiments to refine the final product.

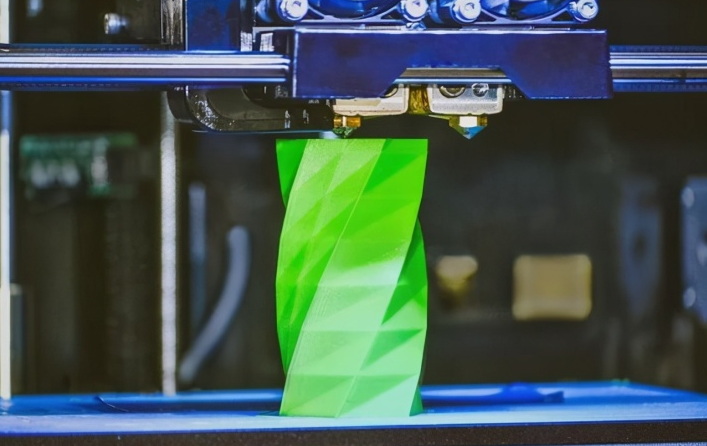

One of the most popular methods of rapid prototyping is through 3D printing. Many industries, including engineering, construction, and manufacturing, use 3D printing as part of their rapid prototyping process to accelerate the workflow and conserve money.

It is worth noting that the terms rapid prototyping and 3D printing are sometimes used interchangeably, which is incorrect. Rapid manufacturing is a process, and 3D printing represents one of the technologies that can be used for this purpose. While prototyping is a very common use for 3D printers, it is also suitable for many other uses and applications.

Why use 3D rapid prototyping?

The goal of any rapid prototyping is to produce a rapid product version that can be used to experiment and test hypotheses. This means you need to make bespoke one-off designs and then modify these in successive iterations. It would help if you produced these iterations as quickly as possible, and the more freedom you have in designing your prototype, the better. Of course, to financially justify your experiments, all of the above requirements need to be available at an affordable price. So let’s see how well 3D rapid prototyping matches up to these criteria.

- Speed

The time from concept to delivery of an idea should be as short as possible. Replacing traditional prototyping processes with months or years of waiting time with days or weeks is a very obvious benefit of rapid prototyping. Compared to any traditional tool-based prototyping process, a 3D printer can create your next iteration precisely from a slightly tweaked design file much faster. Speeding up the design cycle can improve the time to market new products.

- Flexibility

The ability to modify and iterate on custom designs is another strength of 3D rapid prototyping. To 3D prototype an object, you first need to generate a digital 3D model of it. The 3D model can be changed, copied, and shared in many ways. If a series of experiments don’t work, you can load a previous version and try something else. 3D rapid prototyping also gives you a great deal of Flexibility when it comes to the physical properties of your prototype. Some of the properties that can vary depending on the material used are mechanical strength, stiffness, temperature resistance, chemical resistance, dimensional accuracy, and color.

- Cost

Parallel to faster time to market is a reduction in the costs associated with lengthy design cycles. Getting products to market faster will inherently reduce the high Cost of longer, more tool-intensive traditional workflows. Competitive positioning requires development and introduction to be fast, especially in the consumer market. The large-format 3D printer also allows several prototypes to be made simultaneously, resulting in faster decisions when choosing between several looks or feels.

How to incorporate 3D rapid prototyping into your projects?

Rapid prototyping sounds great, but where in the engineering process can it be used? At this point, the answer may not be entirely surprising: 3D rapid prototyping can be useful throughout the process, from the initial proof-of-concept to the pre-production prototype.

- Proof-of-concept prototype (POC)

The proof-of-concept prototype (or concept model) is the earliest prototyping stage. Its purpose is to test the product’s most basic assumptions with as little risk as possible. These prototypes usually have zero regard for the aesthetics or usability of the product. For this reason, POC prototypes usually do not require the level of fidelity offered by 3D printers. However, they can still benefit greatly from the speed and low Cost offered by 3D rapid prototyping.

- Visual prototype

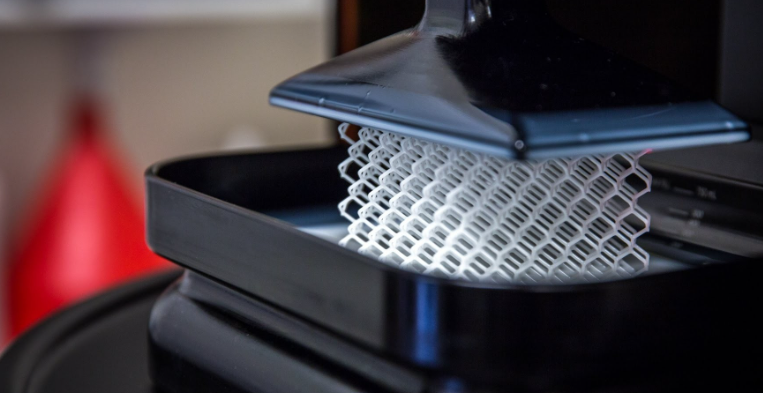

Once a design has been validated in its crudest form, it moves on to the visual design stage. The visual prototype is designed to demonstrate and validate a product’s appearance. This includes its shape, size, color, and texture. In creating this type of prototype, the product’s functionality is secondary. The visual prototype helps the designer decide which materials to use ultimately and how the product will be marketed.

- Functional prototype

Often, parallel prototypes are created to test a product’s separate features in isolation before combining them into a more comprehensive prototype. These prototypes can help designers decide which features are necessary and which are not practical.

- Engineering prototype

Engineering or pre-production prototypes are the final type of prototype in which the findings of all previous prototypes are grafted onto a nearly completed product. These prototypes are often used to present the product to potential investors, customers, resellers, and manufacturers.

Start 3D rapid prototyping with Huapin.

Using 3D printing to accelerate your rapid prototyping process will revolutionize your prototyping workflow. The cost and time savings, coupled with an easier design testing process, make rapid manufacturing one of the best prototyping technologies available.

To start with rapid prototyping and manufacturing, you only need one thing: get a 3D printer or order your parts directly from a 3D prototype service. Then, contact Huapin now and join forces with an on-demand rapid manufacturing producer to implement a new solution through 3D rapid prototyping.